Gantry shearing machine is a large-scale metal sheet processing equipment widely used in the field of metal processing, especially playing an important role in automated production lines. The following is a detailed introduction and features of the device:

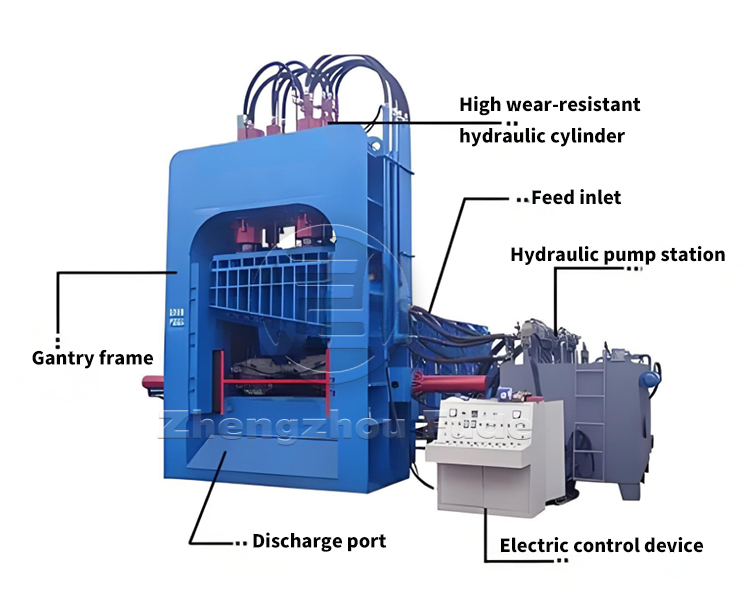

The composition structure of the gantry shearing machine:

- Structure: As the main support of the entire equipment, the gantry structure can withstand high-power servo motors and high-speed movement, ensuring the stability and accuracy of the equipment.

- Workbench: The workbench is equipped with pliers to fix the material to be processed, and the required position is not moved by hydraulic drive.

- Numerical Control System: As the core of controlling the entire equipment, the numerical control system is responsible for calculating fixed input parameters or graphics and generating programs.

- Mobile control system: The program instructions generated by the CNC system are executed into the equipment, and various cutting operations are achieved through motor driven hydraulic cylinders.

- Cutting tool: used to perform cutting operations, usually equipped with precision guiding mechanisms and high-precision hydraulic systems to ensure cutting quality.

Working principle

The gantry shearing machine drives the hydraulic transmission device through an electric motor, thereby driving the presser foot and shearing mechanism to achieve material shearing. During the work process, the automatic feeding box grabs the waste and sends it to the cutting edge, and the feeding speed can be adjusted by a speed regulating motor. For large waste materials, such as scrapped cars, they can be compressed and reduced by a side compression cylinder before being sheared.

Characteristics of Longmen Shear Machine

- Sturdy structure: Adopting a gantry style architecture, it has strong stability and can withstand large tonnage pressures, making it suitable for shearing heavy materials.

- Wide cutting range: The workbench is wide and can continuously or intermittently cut metal sheets of various sizes, suitable for thicknesses ranging from thin to thick plates, such as steel plates, aluminum plates, galvanized plates, etc.

- High precision shearing: Equipped with precise guiding mechanisms and high-precision hydraulic systems, it ensures extremely high straightness and parallelism during the shearing process, improving the quality of the workpiece.

- High degree of automation: Some gantry shearing machines have automation control functions, which control the shearing speed, tension, and number of times through PLC programs, greatly improving production efficiency and operational convenience. At the same time, some models are also equipped with remote control operation functions to achieve remote start, stop, and automatic operation.

- Complete safety protection measures: equipped with various safety protection devices, such as limit switches, grating protection, etc., effectively preventing accidental injuries to operators.

Longmen shearing machine is suitable for industries

- Scrap metal recycling industry: It can easily cut various scrap metals, such as scrap iron, scrap steel, scrap aluminum, scrap car bodies, scrap metal equipment, etc., and process them into small pieces or sheets that are easy to transport and reuse, thereby improving the efficiency and value of scrap metal recycling.

- Metal processing and manufacturing industry: It can be used to cut raw materials such as metal sheets and profiles, providing standard metal parts for subsequent stamping, bending, welding and other processes.

- Metallurgical industry: In the metallurgical industry, gantry shearing machines are often used to process metallurgical waste and scraps. Through cutting processing, these waste materials can be converted into valuable renewable resources, reducing production costs and improving resource utilization.

- Shipbuilding and bridge construction: It can cut large metal components such as ship plates, bridge structural components, etc., providing the required metal materials and components for engineering.

- Automotive industry: In the automotive manufacturing industry, gantry cutters are commonly used to process scrapped car bodies and components. Through cutting processing, these waste materials can be recycled and reused, while reducing environmental pollution.

Zhengzhou Fude Machinery integrates research and development, manufacturing, and sales. We have a professional technical team that deeply understands customer needs, recommends and answers equipment questions for customers, teaches operation techniques, and produces metal compactors, shredders, copper rice machines, plastic crushers, cake presses, and more. If you want to learn about the metal processing, recycling and reuse industry, please consult us.