Industrial shredder

Operation video of metal shredder

The dual axis shredder cuts various soft and hard materials into pieces through two sets of cutterheads made of high-grade alloy steel;

This machine is mainly used for crushing and recycling of thick, tough, and large materials (such as large pipe materials and thick wall waste).

The machine adopts a dense row moving blade structure, equipped with hydraulic drive and forced feeding machinery, which has the characteristics of strong crushing ability and high efficiency.

What is a scrap metal shredder

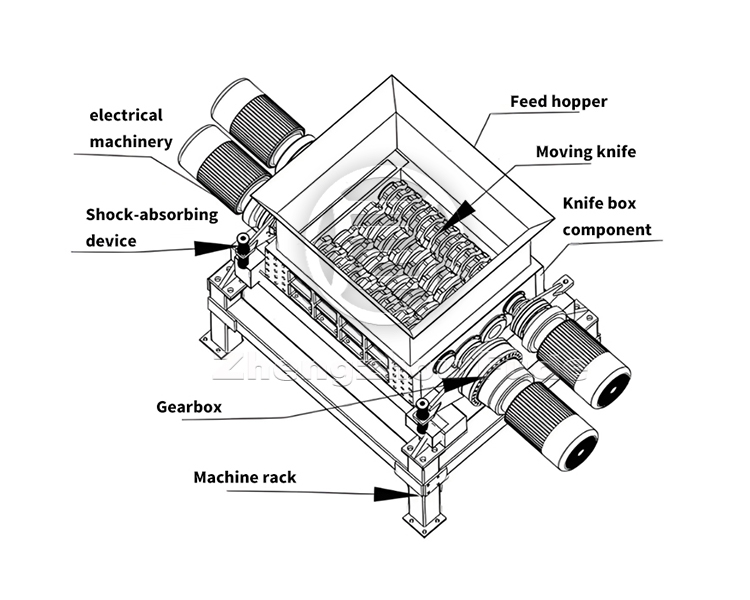

The main component of a dual axis shredder is a rotor with two blades arranged in a spiral pattern. The motor obtains a large torque after decelerating through the reducer, driving the two rotors to move in opposite directions.

During the movement, the blade teeth on the rotor bite the material and pull it into the blades to shear and pull each other, achieving the effect of shredding the material. The twin shaft shredder has low speed and large torque, which is suitable for shredders of various materials.

According to different industries, the twin shaft shredder is mainly divided into: metal shredder, plastic shredder, wood shredder, industrial solid waste shredder, domestic waste shredder, Construction waste shredder, etc. It has a wide range of applications, low noise, no dust and other characteristics.

The degree of fineness of materials shredded by a dual axis shredder is related to the thickness of the shredder blade and the number of blade teeth. The thinner the blade thickness, the smaller the size of the material shredded. The more blade teeth there are, the shorter the length of the material shredded.

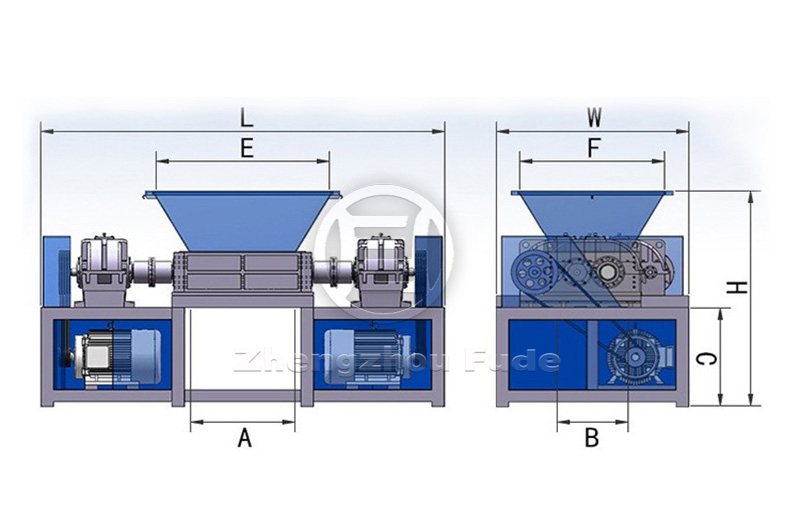

Dual axis shredder chassis

Dual axis shredder single machine

Basic structure of a dual axis shredder

- Bulk material → shredder → conveyor belt → crusher

- After being crushed by a shredder, the volume of large plastic can generally be reduced by 40%, and some materials can even reach 60%.

- Many plastics in our daily lives can be recycled and reused, such as water pipes, gas pipes, large plastic buckets, and so on. As long as we tear it into small enough particles, we can melt it in an extruder and then extrude it for use.

- But the key point is that the plastic waste particles used for feeding must be small enough, as the process before the extrusion granulation process usually involves crushing the plastic first.

- People’s current lives are no longer separated from plastics, which has led to the generation of large amounts of waste plastics. Recycling waste plastics is a big market. The shredder is an efficient and practical helper for plastic recycling.

Illustration of shredder chassis

Shredder blade

Working principle of rubber shredder

Rubber shredder, also known as dual axis shredder, uses two sets of cutting heads made of high-grade alloy steel to cut various soft and hard materials, mainly tearing rubber tires, plastic packaging buckets, car bumpers, baskets, large rolls of film, large bundles of agricultural film covering film, ton bag woven bags, film rolls, fibers, wood, refrigerator shells, etc.

This machine has the characteristics of high output, low energy consumption, low noise, and low dust, and is widely used in various solid waste, plastic, waste electrical appliances, paper, leather, wood, rubber and other coarse shredders.

This machine is mainly used for crushing and recycling thick, hard, and large materials (large pipe materials, thick wall waste).

Overall structure of dual axis shredder

Multi material use of industrial metal shredder

Metal shredder for sale:Widely used in waste plastics, tires, waste rubber, wood, paint barrels, waste home appliance shells (plastic shells, metal shells), waste circuit boards (circuit boards), waste cables, rubber, leather, ton bags, films, and other solid waste, allowing limited resources to circulate indefinitely.

Scrap iron

Scrap iron crushing effect

Crushing effect of waste cardboard boxes

Waste cardboard box

Waste wood

Crushing effect of waste wood barrel

Crushing effect of waste tires

Used tires

Metal shredder machine for sale:customer feedback

On site feedback photos of customers from different regions crushing different materials

Australian customer crushing old clothes on-site

Canadian customer crushing industrial plastics on-site

US customer crushing wood on-site

Austrian customer crushing large blue barrels on-site

Russian customer crushing plastic bottles on-site

Double axis industrial shredder shipped

The factory arranges different logistics vehicle sizes according to the customized machine models and sizes of different customers, ensuring timely delivery and reliable transportation

Customized machine shipment from Russian customers

Customized machine shipment for American customers

Malaysian customer machine shipment

How to choose a dual axis shredder correctly?

Firstly, when choosing a dual axis shredder, it is necessary to consider the properties of the material being processed, such as size, shape, hardness, etc., to ensure that the machine can effectively crush the material.

Secondly, the amount of processing capacity is also crucial when selecting a machine, as it directly affects the work efficiency and production capacity of the machine.

The corresponding model can be selected based on the amount of processing required per hour, and the selected model can ensure that it can meet production needs through the two key factors of material and processing capacity. (Customizable models according to customer needs)

Fudemetal Crusher

Fudemetal Crusher