Rubber Shredder

Working video of dual axis shredder

The dual axis shredder uses two sets of cutterheads made of high-grade alloy steel to shear each other and shred various soft and hard materials.

This machine mainly crushes and recovers ultra-thick, tough, and large materials (large pipe materials, thick wall waste).

The machine adopts a dense row moving blade structure, equipped with hydraulic drive and forced feeding machinery, which has the characteristics of strong crushing ability and high efficiency.

What is a dual axis shredder?

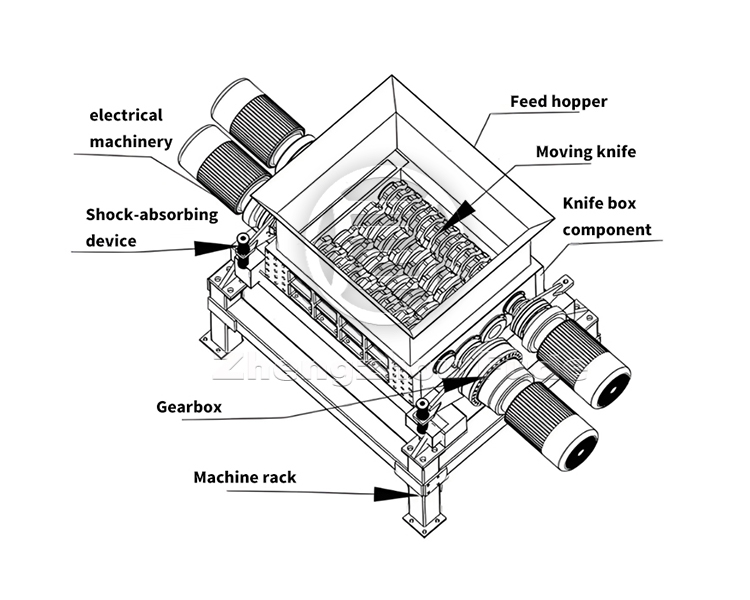

Double axis shredder, also known as shear shredder, reduces material size through shearing, tearing, and squeezing. Its main shaft is forged solid and tempered.

The internal structure adopts a dense row moving blade structure and a hydraulic driven push plate forced feeding mechanism, which has strong crushing ability, stable performance, high efficiency, low temperature, and convenient operation.

This shredder is widely used in waste plastics, waste rubber, Drink can, iron sheet, cloth, waste paper, wood and other large volume wastes, providing reliable equipment for the crushing and volume reduction treatment of waste recycling in the early stage of our country.

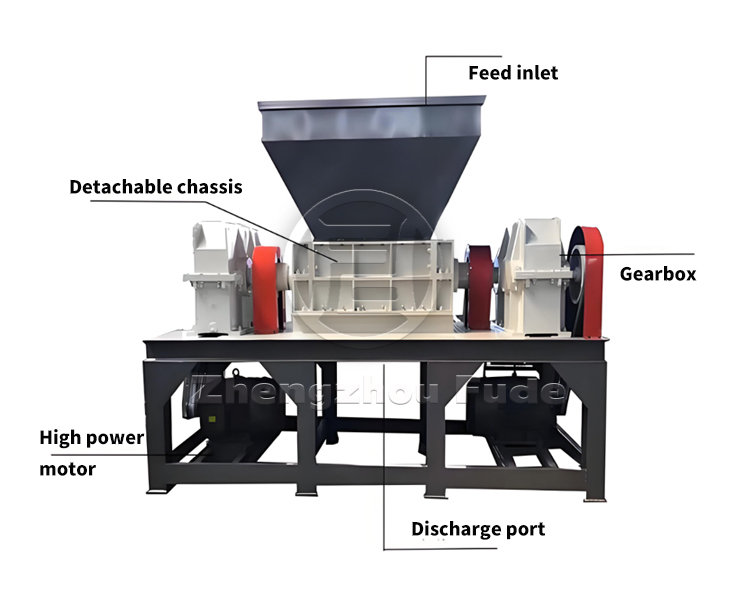

Dual axis shredder single machine

Machine structure diagram of dual axis shredder

Product characteristics of metal shredder

1.The blade holder and blade on the rotor are detachable, making it easy to clean, maintain, and maintain.

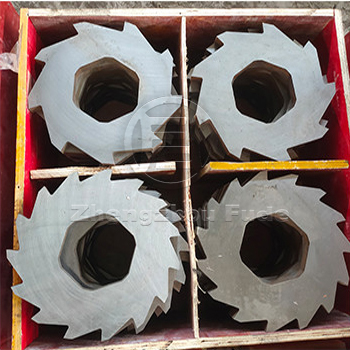

- Each moving blade has 4 cutting edges that can be rotated 90 ° for continued use after wear.

- The main shaft is driven by a gear reducer, running smoothly, with low noise and high torque.

- Adopting a PLC program control system, it can automatically reverse and forward, ensuring stable machine operation.

- The box is welded and tempered after welding.

- The installation position of the moving knife should be such that the gap between the moving knife and the fixed knife is the same.

- The movable blade holder is connected to the blade shaft with screws in an embedded manner, which can avoid the phenomenon of blade falling caused by welding after long-term vibration.

- After shredding, transportation is convenient, transportation costs are low, transportation efficiency is increased, and secondary processing is convenient.

Shredder blade

coupling

Shredder Spacer

Gearbox

Working principle of dual axis industrial crusher

The twin shaft shredder cuts various soft and hard materials through two sets of cutter heads composed of high-grade alloy steel, mainly tearing plastic packaging barrels, rubber tires, car bumpers, baskets, large rolls of film, large bundles of agricultural film mulching films, large bundles of packaging plastic films, large bundles of packaging ton bags woven bags, roll of film, Tetra Pak packaging boxes, SIG Combibloc Group, paper, fiber, wood, refrigerator shells, etc.

This machine has the characteristics of high output, low energy consumption, low noise, and low dust, so it is widely used in various solid waste, plastics, waste appliances, paper, leather, wood, rubber, and other coarse shredding and tearing machines. This machine is mainly used for crushing and recycling of thick, tough, and large materials (large pipe materials, thick wall waste materials).

The machine adopts a dense row moving blade structure, equipped with hydraulic drive and forced feeding machinery, with strong crushing capacity and high efficiency.

Shredder machine box

Illustration of shredder chassis

The versatility of industrial shredders

Widely used in waste plastics, tires, waste rubber, wood, paint barrels, waste home appliance shells (plastic shells, metal shells), waste circuit boards (circuit boards), waste cables, rubber, leather, ton bags, films, and other solid waste, allowing limited resources to circulate indefinitely.

Big Blue Bucket

The crushing effect of the large blue barrel

Old tires

Crushing of waste tires

Scrap metal

Scrap metal crushing effect

Waste wood

Crushing effect of waste wood

Double shaft shredder for sale: customer feedback

On site feedback photos of customers from different regions crushing different materials

Australian customer crushing old clothes on-site

Canadian customer crushing industrial plastics on-site

US customer crushing wood on-site

Austrian customer crushing large blue barrels on-site

Russian customer crushing plastic bottles on-site

wood shredder harbor freight

The factory arranges different logistics vehicle sizes according to the customized machine models and sizes of different customers, ensuring timely delivery and reliable transportation

Customized machine shipment from Russian customers

Customized machine shipment for American customers

Malaysian customer machine shipment

Wood pallet shredder manufacturer

When choosing a biaxial shredder, it is necessary to consider the characteristics of the processed material, such as size, shape, hardness, etc., to ensure that the machine can effectively crush the material.

Secondly, when choosing a machine, the size of its processing power is also crucial, as it directly affects the machine’s work efficiency and production capacity.

The corresponding model can be selected based on the required processing volume per hour, and the selected model can ensure that it can meet production needs through two key factors: material and processing capacity. (Model can be customized according to customer needs)

Fudemetal Crusher

Fudemetal Crusher