Latest discounted price for metal block press

800Metal compactor is a mechanical equipment mainly used to compress raw materials such as metal shavings, particles, powders, etc. into high-density compacts.

View detailsSearch the whole station

The working principle of the box type cake press is mainly based on the principle of hydraulic transmission, especially when dealing with metal shavings, its working process is particularly typical. The following are the detailed steps for the operation of the box type cake press:

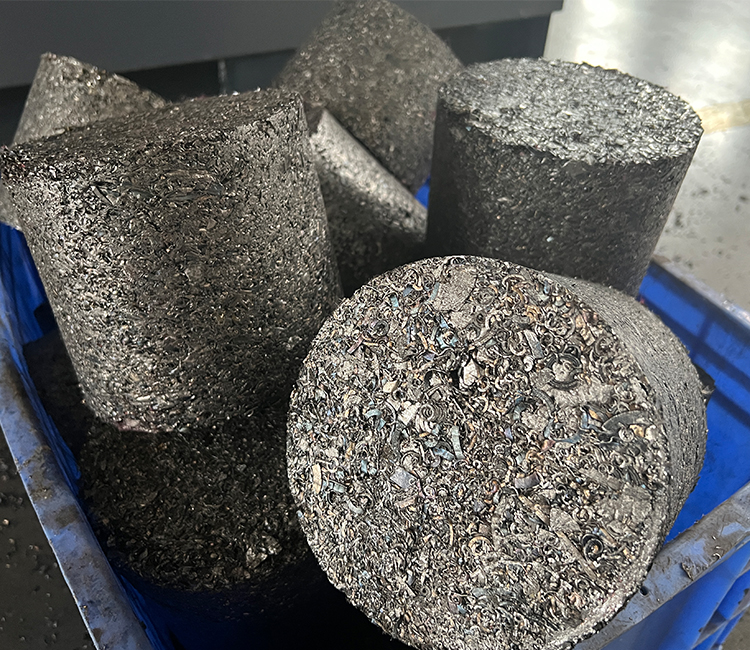

Box type cake press is an efficient and multifunctional compression device, mainly used to compress various loose metal shavings, metal powders, metal pins, metal shavings and other materials into dense cake blocks. This type of equipment has a wide range of applications in industries such as metal processing, casting, smelting, and mechanical processing. It can effectively reduce material volume, facilitate storage and transportation, and also help with recycling and reuse.

The box type cake press provides strong pressure through a hydraulic system, compressing loose metal shavings or other materials into tight cakes. In this process, the hydraulic system is a key part, which uses the pressure of hydraulic oil to push the piston to move, and then drives the pressure head to squeeze the material.

In summary, the box type cake press compresses loose metal shavings or other materials into tight cakes through the powerful pressure provided by the hydraulic system, which has the advantages of high efficiency, energy saving, and environmental protection.

Zhengzhou Fude Machinery integrates research and development, manufacturing, and sales. We have a professional technical team that deeply understands customer needs, recommends and answers equipment questions for customers, teaches operation techniques, and produces metal compactors, shredders, copper rice machines, plastic crushers, cake presses, and more. If you want to learn about the metal processing, recycling and reuse industry, please consult us.

Metal compactor is a mechanical equipment mainly used to compress raw materials such as metal shavings, particles, powders, etc. into high-density compacts.

View detailsBox type cake press is a mechanical equipment specifically used to press various powdered or granular raw materials into cakes or flakes with a certain shape and density.

View detailsThe machine used to manufacture pressed blocks compresses them into blocks or cakes through pressure for storage, transportation, or further processing.

View detailsThe metal compactor can press waste materials, aluminum shavings, cans, etc. into cubes, rectangles, and cylinders

View details