Gantry Metal Shear

Large multifunctional scrap metal shearing machine

| Product features | Automatic |

| Processing customization | Support customization |

| Applicable objects | Scrap metal treatment and processing, recycling in utilization |

The gantry shear (also known as the portal shear or upgraded crocodile shear) is a large-scale metal processing machine that uses a hydraulic or mechanical transmission system to drive the blades in a reciprocating cutting motion.

Its core design draws inspiration from the sturdy frame structure of a “gantry crane,” combining a high-rigidity machine body with a powerful shearing system.

It is specifically designed for processing large-sized, high-hardness metal scrap and is widely used in heavy industries such as scrap metal recycling, automobile dismantling, metallurgy and casting, and ship dismantling.

Working video of gantry shearing machine

The principle of this machine is to use an automatic feeding box to grab the material from the upper feeding box, and then send it to the cutting edge by the conveyor belt.

The feeding speed can be controlled by a speed regulating motor.

If large waste cannot pass through the gantry cutting edge, the waste can be compressed and reduced by the side compression oil cylinder, and then sent to the cutting edge through the conveying platform for cutting.

Large Metal Shears Product Introduction

The Industrial metal shears is a high-precision metal material cutting equipment, mainly used for the two directional fixed length cutting of longitudinal rings of materials such as steel plates and profiles.

It is driven by hydraulic pressure,; The body part is a mechanical structure with a double column guiding form, making the machine run more smoothly;

The blade system is equipped with a shock-absorbing rubber device, which can effectively reduce the generation of vibration and noise.

Heavy duty gantry shearing machine

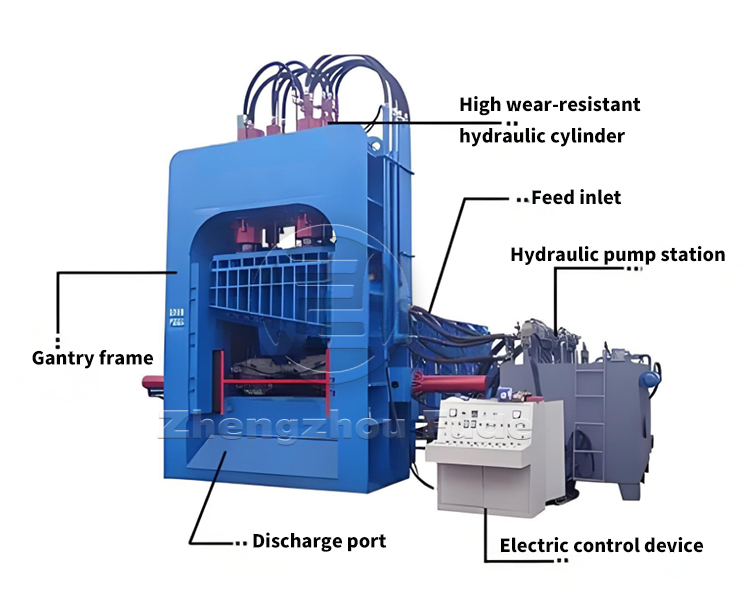

The structural principle of the gantry shearing machine

Structural diagram

In principle, the scrap steel shearing machine uses an automatic feeding box, which means that after the material is grabbed from the upper feeding box, the waste is automatically sent to the cutting edge by the conveyor belt, and the feeding speed can be adjusted by the speed regulating motor.

There are side compression cylinders on both sides of the material box. For large waste materials such as scrapped cars that cannot pass through the gantry shear blade, they can be compressed and reduced by the side compression cylinder, and then sent to the shear blade through the conveyor platform for cutting.

Gantry frame

- Constructed from high-strength steel plates welded into a “door” shape structure, optimized through finite element analysis, it can withstand shear forces of several thousand tons without deformation.

- Typical dimensions: span 3-8 meters, height 2-5 meters, suitable for the shearing requirements of different specifications of metal materials.

hydraulic transmission system

- Power source: An electric motor drives a high-pressure oil pump to deliver hydraulic oil to various actuators.

- Core components:

- Shearing cylinder: Pushes the blade to perform vertical shearing actions.

- Pressure cylinder: Secures the metal material to prevent slippage during shearing, improving shearing accuracy.

- Feed cylinder: Automatically pushes the metal material into the shearing area to enable continuous operation.

- Advantages: Compared to mechanical transmission, hydraulic systems feature low noise, minimal impact, and strong overload protection capabilities.

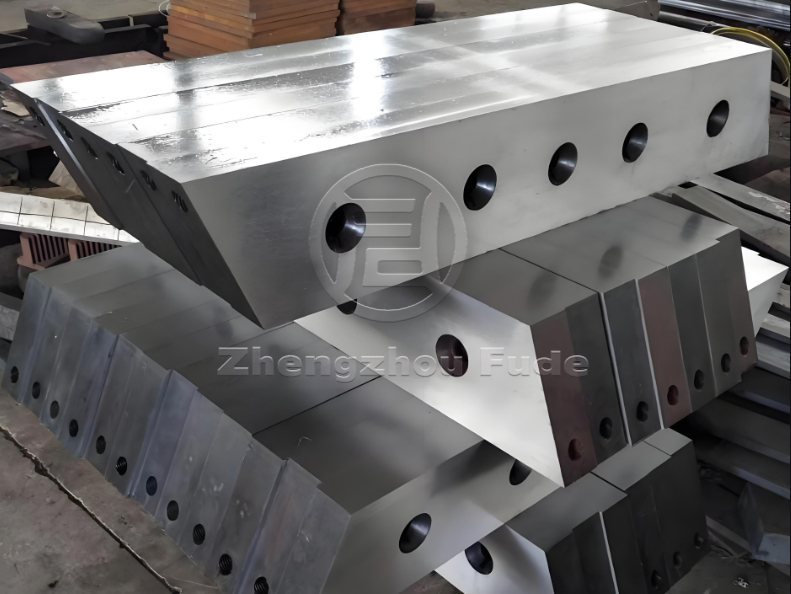

blade system

- Material: Made of alloy tool steel such as H13 and D2, laser hardened to a hardness of HRC58-62.

- Design: Adjustable cutting edge to accommodate different thicknesses of metal; some models are equipped with rotating blades to extend service life.

Product parameters of scrap metal cutting machine

| Product model | Maximum shear force | Bin size (mm) | Opening height (mm) | Knife edge length (mm) | Output (t/h) | Shear frequency (times/minute) | Main motor (kW) |

| 315 | 3150 | 3000*1200*800 | 400 | 1200 | 4-8 | 3-4 | 90 |

| 630 | 6300 | 800*1800*900 | 500 | 1800 | 4-8 | 3-4 | 225 |

| 1250 | 1250 | 8000*2000*1200 | 700 | 2000 | 4-8 | 3-4 | 405 |

Metal shearing equipment for multifunctional use

The shearing machine equipment is mainly suitable for cutting metal sheets such as steel plates, angle steels, channel steels, steel bars, square steels, square tubes, and scrap aluminum alloys.

Square tube

Square steel

Scrap material

Scrap steel bars

I-beam

Angle steel

Scrap steel plate

Steel pipe

Core application scenarios

Scrap metal recycling

- Scrap car bodies, industrial scrap steel, steel structures, etc. are cut into standard sizes for easy re-melting in furnaces.

- Case study: After using a gantry shear, a recycling plant in China increased its metal recovery rate from 85% to 98.7% and achieved a daily processing capacity of 300 tons.

car dismantling

- Shear high-strength boron steel from the A-pillar, B-pillar, chassis, etc. of automobiles, and then flatten the car body with a compression device before cutting it.

- Efficiency: The processing time for a single car has been reduced from 2 hours to 18 minutes.

metallurgical industry

- Shearing precious metals such as nickel plates and titanium plates to meet aerospace-grade flatness requirements.

- Case study: Baowu Group used a 1,500-ton gantry shear to reduce nickel plate shearing costs by 40%.

Ship dismantling

- Cut the steel plates of the ship’s hull and use flame cutting to complete the dismantling of large structures.

Longmen Scissor Head

Control box for gantry shear

Metal Shearing Equipment Product Features

- Add a high-pressure filter to the hydraulic system. The hydraulic oil needs to pass through a high-pressure filter before entering the pipeline and hydraulic control valve. (High pressure filter comes with alarm)

- Independent air cooling: This machine adopts a high air flow air cooling machine to control the oil temperature of the hydraulic oil within the normal range of use. At the same time, the air-cooled machine solves the problem of inconvenient water sources due to the occupied area of the water cooler.

- PLC manual automatic control box. Can achieve manual and automatic replacement. Equipped with a remote control for remote start, stop, and automatic operation.

- Pushing groove with pressure cover: It can achieve automatic feeding and simultaneously push the material along the pressure cover to the main cutting machine for cutting.

- Connecting device at the front end of the cylinder rod. Effectively protect the cylinder rod from damage.

Metal shears for sale at favorable prices

We have consulted and followed up with our cooperative clients from countries such as the United States, Canada, Mexico, Germany, Russia, and Italy on the effectiveness of using gantry shearing machines. They have given a very satisfactory response, stating that the failure rate is very low, the cutting surface is large, and the operation is safe.

American customer cutting steel plate on-site

Canadian customer cutting aluminum alloy sheet material on-site

Mexican customer cutting square tube on-site

German customer cutting I-beam on-site

Russian customer cutting waste on-site

Italian customer cutting scrap iron on-site

How to choose a suitable gantry shearing machine

When choosing a gantry shearing machine, the following points need to be considered:

- Cutting ability: Select the appropriate cutting ability according to actual needs to adapt to the specifications and thickness of the material to be cut.

- Blade material: The material of the blade directly affects the cutting effect and efficiency, and high-quality alloy steel and other high-strength, wear-resistant materials need to be selected.

- Transmission system: The stability and reliability of the transmission system determine the overall performance and service life of the equipment, and high-quality transmission components and designs should be selected.

- Automation level: Choose manual, semi-automatic, or fully automatic gantry shearing machines as needed to improve production efficiency and reduce labor costs.

(Suitable machine models can be customized according to specific customer needs)

Metal Shearing Machine Price, Shearing Machine Equipment Manufacturer

Customized machine shipment inspection

As a “heavy-duty weapon” in the field of metal processing, the gantry shear is continuously promoting global circular economic development through technological innovation.

From Mumbai to Rotterdam, from Detroit to Shanghai, this equipment has become an indispensable part of modern industrial infrastructure.

Fudemetal Crusher

Fudemetal Crusher