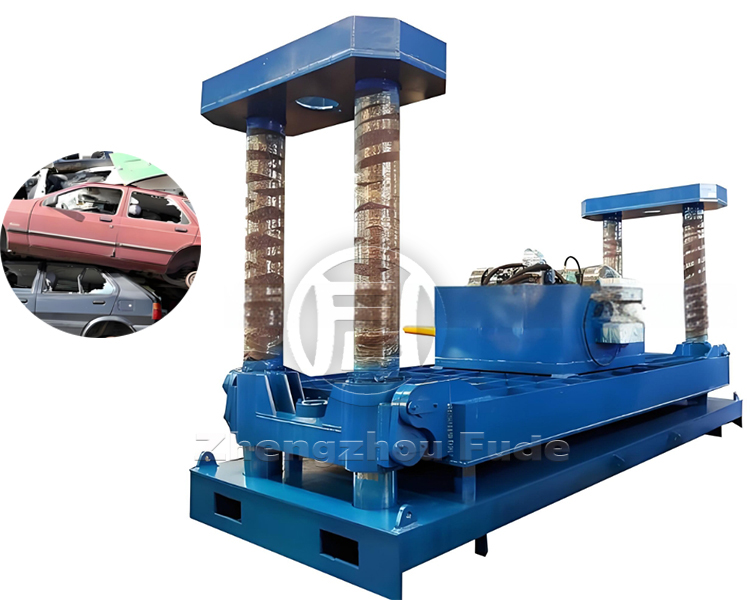

Automobile Flattening Machine

Large Scrap Car Flattening Machine

Processing customization: Support customization

Type: Briquetting press

Usage: Scrap car shell flattening

Model: Multiple specifications (customizable as needed)

A car baler, also known as a vehicle baler or scrap car compressor, is an industrial device specifically designed to compress large metal vehicles such as scrap cars, trucks, and buses into flat blocks or rectangular shapes.

Its core purpose is to reduce the volume of vehicles through high-pressure physical compression, facilitating subsequent transportation, storage, and metal recycling.

Working video of car flattening machine

The hydraulic system of the car flattening machine consists of a fuel tank, pump, control valve, oil cylinder, etc., and achieves car flattening through the transmission of force through high-pressure liquid.

The working principle includes pump extraction of hydraulic oil, control valve adjustment of flow direction and pressure, and hydraulic cylinder driving of pressure plate operation.

Large Scrap Metal Briquetting Machine Product Introduction

The basic principle of an automobile flattening machine is to use the plastic deformation property of metal materials under external forces to provide sufficient external forces that can aggregate and produce deformation, thereby forming tight bundles.

So metals that cannot undergo plastic deformation or have very small plastic deformation cannot be directly packaged. Products such as high carbon steel, tool steel, steel wire ropes, and cast iron cannot be directly packaged on the machine.

The core function of a car baler is to use a high-pressure hydraulic system to quickly compress scrap vehicles into high-density metal blocks, reducing their volume by more than 80% to lower transportation and storage costs.

At the same time, it provides standardized raw materials for subsequent metal crushing and sorting, improving the recovery rate of resources such as steel and aluminum, and effectively preventing oil leakage and environmental pollution.

Ultimately, it promotes the efficient conversion of automotive waste from “end-of-life disposal” to “resource regeneration.”

Hydraulic metal briquetting machine product features

- It is driven by hydraulic pressure and operates smoothly.

- Adopt manual or PLC automatic control operation mode.

- There are four types of discharge methods: side flipping bag, side pushing bag, front pushing bag, or no discharge bag.

- Installation does not require foot screws, and diesel engines can be used for power in areas without power supply.

- Product specifications and types: The automobile flattening machine has 63 tons to 600 tons, 10 varieties, and more than 20 specifications, which can meet the different needs of customers at different levels.

Car flattening machine

Car flattening machine presses waste cars

| Product Name | Metal scrap briquetting machine |

| Bag size | 2000*450(3-4Vehicle) |

| Applicable materials | Various scrapped vehicles |

| Efficiency | About 20 vehicles/hour |

| Motor power | 30kw |

| Equipment characteristics | PLC control, high degree of automation, simple operation, and strong equipment stability |

Industrial Metal Briquetting Machine Product Advantages

- The transportation of metal materials after pressing is convenient, which can effectively reduce transportation costs and increase transportation efficiency;

- After pressing, the metal is easily crushed for secondary processing;

- Block metal materials are easier to store compared to metals, which can save a lot of warehouse space;

- Pressing metal blocks facilitates application and reprocessing.

After flattening with a car flattener

Wide range of applications for industrial metal compactors

Mainly suitable for sedans, commercial vehicles, vans, large trucks, motorcycles, electric vehicles, etc

Automobile balers, with their high-efficiency compression and environmentally friendly processing capabilities, are widely used in scrap automobile recycling and dismantling companies, automobile manufacturers’ defective product processing lines, insurance companies’ accident-damaged vehicle disposal centers, government and military vehicle disposal projects, and the front-end pre-processing stages of large-scale scrap metal smelting plants.

By quickly compressing various types of scrap vehicles into standardized metal blocks, they significantly reduce transportation and storage costs while facilitating subsequent automated crushing and sorting processes.

Additionally, they prevent oil leaks from polluting the environment, making them a core piece of equipment in the automotive industry’s circular economy chain for maximizing resource utilization and minimizing pollution control.

Sedan

Business vehicle

Car Large trucks

Motorcycle

Van

Electric vehicles

How to choose Metal Briquette Machine equipment

- Power and pressure: Different flattening machines have different power and pressure. If the metal material to be processed is thicker or harder, it is necessary to choose a machine with higher power and pressure.

- Precision and stability: The precision and stability of the flattening machine are key factors affecting product quality, so special attention should be paid when selecting.

- Operation and maintenance: The simplicity of operation and maintenance is also one of the factors that needs to be considered. If the operation and maintenance of the machine is more complex, it will increase the cost of use.

- Metal briquetting machine price: different models and sizes determine the different price range, we can customize the right briquetting machine according to the customer’s requirements for the output of the equipment, the hardness of the material.

Scrap metal compactors sale

We followed up with Italian and French customers on the effectiveness of using car flattening machines, and they said they pay more attention to details. The machine is thickened as a whole, wear-resistant and durable, and has sufficient power. They really need such a useful equipment.

French customer’s car flattening scene

Italian customer’s car flattening scene

Car crushing machines are a key link in the scrap car disposal industry chain, enabling efficient compression to maximize resource utilization and minimize environmental pollution. With the global increase in car ownership and the promotion of circular economy policies, market demand for these machines will continue to expand, and technology will evolve toward intelligent and green solutions.

Fudemetal Crusher

Fudemetal Crusher