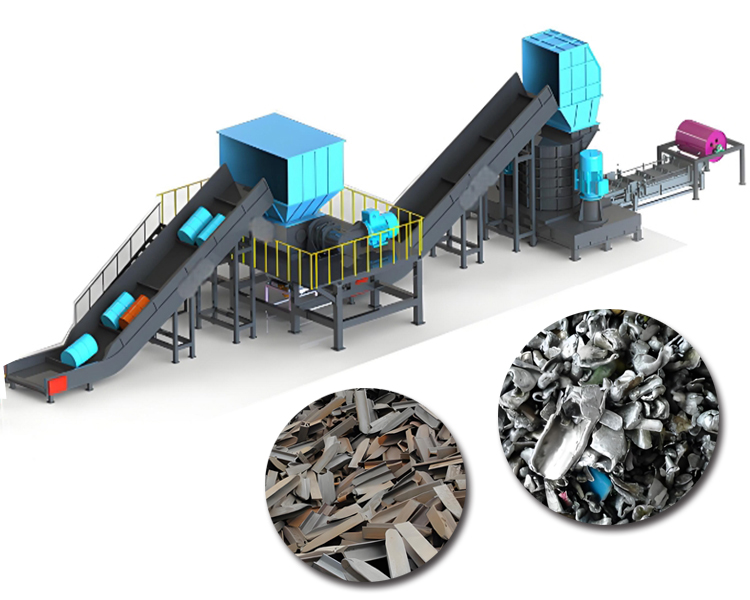

Large metal shredder equipment

Configuration of metal crushing production line

Applicable materials: tires, wood, metal; Equipment configuration: conveyor, dual axis shredder, magnetic separator, chain conveyor, rubber pellet machine, dust removal equipment, vibrating screen.

Output: configured according to customer requirements.

Work video of dual axis shredding production line

The Double Shaft Shredder cuts various soft and hard materials into pieces through two sets of cutterheads made of high-grade alloy steel;

This machine is mainly used for crushing and recycling of thick, tough, and large materials (such as large pipe materials and thick wall waste).

The machine adopts a dense row moving blade structure, equipped with hydraulic drive and forced feeding machinery, which has the characteristics of strong crushing ability and high efficiency.

What is a scrap metal shredder

The scrap metal crushing production line is an efficient, environmentally friendly, and energy-saving waste metal processing equipment with strong processing capacity, environmental protection and energy conservation, simple operation, and wide application.

The core technology is shredding technology, which uses high-speed rotating blades to tear and crush scrap metal. Applicable scenarios include waste car tire processing centers, rubber product processing enterprises, construction waste disposal centers, agricultural machinery maintenance centers, and urban waste disposal centers.

With the increasing awareness of environmental protection and the scarcity of resources, the scrap metal crushing production line has broad market prospects.

Configuration Table of Metal Crushing Production Line

The scrap metal crushing production line is an efficient, environmentally friendly, and energy-saving waste metal crushing and processing equipment.

Twin Shaft Shredder

The Twin Shaft Shredder is mainly used to shred and process various large materials, and the shredded materials can be directly recycled and reused after processing.

Magnetic separator

Magnetic separator is one of the most widely used and versatile models in the industry, suitable for separating substances with magnetic differences.

Magnetic separators are widely used in industries such as mining, timber, kilns, chemistry, and food.

Rubber pellet machine

Rubber pellet machine is a product that processes waste rubber products, scraps, and tires into rubber pellets.

Rubber pellet machines can be divided into two types: one is based on the principle of fixed blade and moving blade shearing. The other is the principle of throwing a knife to break.

Dust removal equipment

Vibrating screen

Metal shredder machine for sale:Customer Feedback

We consulted and followed up with customers from countries such as the United States, Austria, Russia, and Australia, and achieved satisfactory results in the use of shredding production lines.

Wood crushing production line

Waste plastic crushing production line

Scrap metal crushing production line

Scrap tire crushing production line

The process flow of metal crushing production line

- Feeding stage: Waste metal is transported to the feeding port of the shredder. Some shredders may be equipped with conveyor belts or other devices to transport scrap metal to the feeding port of the shredder.

- Pre treatment: In the vicinity of the feed inlet, preliminary classification and treatment may sometimes be carried out, such as removing large debris or non-metallic substances. This can be done manually or automatically to ensure that the shredder receives pure metal materials.

- Shredding stage: After the scrap metal enters the shredder, the blades or hammers inside the machine begin to shred the metal. Shredders typically use high-speed rotating blades or hammers to transform scrap metal from larger blocks into smaller fragments.

- Screening and separation: During the tearing process, some smaller metal fragments may mix with other debris, such as plastic, rubber, etc. Screening and separation equipment will separate metal fragments from other debris, usually using equipment such as vibrating screens and magnetic separators.

- Reprocessing: Some shredders may also be equipped with other reprocessing equipment, such as magnetic separators for removing magnetic impurities, or air flow separators for removing lightweight impurities. These reprocessing steps aim to further improve the metal recovery rate and purity.

- Collection and packaging: After screening and reprocessing, the metal fragments obtained are collected. Usually, containers, bags, or other packaging materials are used to load metal fragments for transportation and subsequent processing.

- Transportation and storage: The loaded metal fragments will be transported to the storage area. In the storage area, metal fragments may be temporarily stored until sufficient quantity is available for the next step of recycling processing.

The specific implementation methods may vary depending on the model, manufacturer, and type of metal being processed of the shredder.

What are the factors affecting the price of shredder equipment

The cost of raw materials can affect the price of shredder equipment. Raw materials mainly refer to the bearings, spindle, and cutter head of the machine and other accessories;

The quality of materials directly affects the performance and crushing effect of the shredding equipment. If the equipment materials are good, then the shredding equipment produced is of high quality, good performance, durable and durable, and of course, the price is also high. Secondly, there are production processes, and the shredder equipment produced by different processes will have significant differences in performance.

Furthermore, market factors in different regions can also affect the prices of shredder equipment. The demand for metal shredder equipment varies in different regions, resulting in different market conditions. This is also one of the main factors affecting the prices of shredder equipment.

Large scale metal shredding production line

Scrap metal crushing

Crushing of waste wood

Crushing of waste tires

Crushing of waste cardboard boxes

Fudemetal Crusher

Fudemetal Crusher