plastic crusher machine

Multifunctional Powerful Plastic Crusher

power:7.5kw

diesel engine:32 horsepower

degree of comminution:Medium crushing

Crushed materials:Fruit plastic basket, plastic bottle, tire, car bumper, PC, PP

quality assurance:a year

As the global demand for plastic recycling grows, plastic crushers have become indispensable equipment for transforming waste plastics into reusable raw materials. Designed for efficiency, durability, and versatility, these machines are widely used in recycling facilities, manufacturing plants, and waste management centers worldwide.

What are the characteristics of plastic crushers

Plastic crusher as the key equipment for waste plastics recycling, with high efficiency, durability, adaptability of the significant features. Its use of high-strength alloy knives and optimized design of the blade structure, can quickly crush all kinds of hard, soft or tough plastic, such as PET bottles, PE film, PP pipe, etc., crushing particle size uniformity and stable yield;

Equipment equipped with high-power drive motors and low-noise deceleration system, in order to achieve high-speed crushing and at the same time effectively reduce the energy consumption and vibration of the operation;

Modular design is easy to dismantle and clean, anti-jamming automatic reversing Modular design is easy to disassemble and clean, anti-jamming automatic reversing function can avoid equipment overload damage, with sealed dustproof structure to reduce dust spillage;

In addition, the whole machine is made of wear-resistant steel, the key components are strengthened by heat treatment process, which can withstand high-load operation for a long time, and it is suitable for the continuous production needs of plastics processing factories, recycling stations and other scenarios.

Plastic crusher production line

Plastic Bottle Crusher Parameter Table

| model | production/kg | electrical machinery/kw | size/mm | Overall weight/kg |

| 400 | 200-300 | 7.5 | 1100*650*1200 | 350 |

| 600 | 500-700 | 18.5 | 1500*850*1750 | 500 |

| 800 | 800-1000 | 30 | 1800*1200*1850 | 900 |

| 1000 | 1000-1300 | 37 | 1950*1700*1900 | 1350 |

| 1200 | 1500-2000 | 45 | 2150*1950*2000 | 1800 |

plastic crusher machine finished product display

Key Features & Benefits

- High Efficiency: Heavy-duty motors and precision-engineered blades ensure rapid crushing with low energy consumption.

- Versatile Applications: Handles rigid plastics (HDPE, PET, ABS), soft films (PE, PP), and engineered composites.

- Adjustable Output: Interchangeable screens allow customization of granule size for different downstream processes.

- Durable Design: Hardened steel blades resist wear, while soundproof casings minimize noise pollution.

- Safety First: Emergency stop buttons, overload protection, and enclosed chambers prevent accidents.

- Eco-Friendly: Reduces plastic waste volume by up to 80%, lowering landfill dependency and carbon footprint.

plastic crusher machine

crusher machine for plastic

plastic bottle crush

plastic bottles crusher

should you crush plastic bottles for recycling

2l plastic bottle crusher

The working principle of crusher machine for plastic

Plastic pulverizer crushes large plastic products into small particles or powder by mechanical force (e.g. shear, impact, extrusion). Its core process includes:

- Feeding system: waste plastics (e.g. plastic bottles, films, pipes, injection molding waste, etc.) are fed into the crushing chamber by conveyor belt or manually.

- Crushing chamber: The high-speed rotating blade (or hammer head) cooperates with the fixed knife plate to cut, tear and squeeze the plastic.

- Screen filtering: the crushed materials are separated through the screen, the particles that do not meet the size requirements are returned to be re-crushed, and the qualified particles are discharged through the discharge port.

- Dust removal system (optional): some models are equipped with dust removal device to reduce dust pollution and meet the requirements of environmental protection.

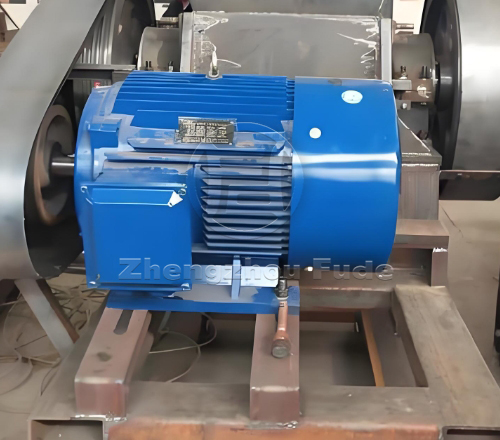

Motor configuration

Crusher blade

Diesel engine configuration

How to choose a plastic bottles crusher price

- Crushing ability: The crushing ability directly determines the working efficiency of the plastic crusher. Select equipment with appropriate crushing capacity based on your production needs.

- Speed: Plastic crushers with higher speeds have better crushing effects, but their prices may be relatively high. You need to balance production efficiency and budget.

- Fineness: Fineness directly affects subsequent processing and production. You need to choose the corresponding fineness according to production needs.

- can and plastic crusher: mainly used for crushing waste plastics and factory plastic scraps. You can choose different types of plastic crushers according to your needs.

Why Choose Our Plastic Crushers?

- Compliance: Meets CE, ISO, and other international safety/environmental standards.

- Customization: Tailor motor power, blade configuration, and chamber size to your specific needs.

- Global Support: 24/7 technical assistance and spare parts availability in 50+ countries.

- Proven Track Record: Trusted by Fortune 500 companies and SMEs across 80+ nations.

plastic crusher for sale

Customized wooden box packaging for customers

should i crush plastic bottles for recycling

Core Advantages

The core advantage of the plastic crusher is that it combines high-efficiency crushing, widely applicable and stable and reliable in one: equipped with high hardness alloy knives and intelligent speed control system, for different materials, thickness of plastic products to achieve rapid refinement of the crushing, processing efficiency of the traditional equipment to enhance the more than 30%;

Modular knife and adjustable screen design, flexible control of the material particle size (5-30mm adjustable), and at the same time, with the overload protection, automatic reversal of obstacles and fully enclosed noise structure to ensure that the equipment continuous high-load operation in the failure rate of less than 5%, significantly reducing maintenance costs.

Overload protection, automatic reversal of obstacles and closed noise reduction structure to ensure that the equipment in the continuous high-load operation of the failure rate of less than 5%, significantly reducing maintenance costs, and become the first choice of equipment for the plastic recycling industry to enhance the utilization of resources and production efficiency.

application scenario

In terms of product usage, plastic crushers can be used to crush various types of waste plastic bottles, beverage packaging paper, beverage bottles, mineral water bottles, plastic buckets, oil buckets, paint buckets, tires, waste rubber, wood, woven bags, plastic pipes, waste machine head materials, greenhouse roll films, waste home appliance shells, waste circuit boards, rubber, leather, ton bags, films, plastic steel, car bumpers, plastic films, and other waste plastics.

After being processed by plastic crushers, waste plastics have advantages such as uniform particles, non deterioration, and low temperature. Due to its excellent standards in the processing of waste plastics and flexible materials, this machine has been recognized by most foreign waste plastic recycling and plastic product enterprises. Favorite.

Fruit transport basket

plastic bucket

Leftover material

Wire and cable sheath

Effect diagram of fruit transportation basket crushing

Plastic bottle crushing effect diagram

Effect diagram of edge material crushing

PP material crushing effect diagram

Precautions for using a plastic crusher

1.Uniform feeding: During the operation, the feeding should be uniform to avoid adding too much plastic at once to prevent blocking the crushing chamber. At the same time, do not work excessively for a long time to avoid damage to the equipment.

2.Do not reach your hands into the feeding port: During operation, do not reach your hands into the feeding port to avoid accidental injury.

3.Maintenance and upkeep: The maintenance and upkeep of equipment must be carried out by professional technical personnel and cannot be operated without authorization. Regularly clean, lubricate, and tighten the equipment to ensure its normal operation.

4.Check the safety protection device: The safety protection net and protection device of the plastic crusher must ensure that they do not deform, fail, and are safe and reliable. If there is any damage or failure, it should be replaced or repaired in a timely manner.

Join the Circular Economy Revolution

By investing in a high-quality plastic crusher, businesses can:

- ✅ Reduce raw material costs by up to 40% through recycling.

✅ Comply with global sustainability regulations (e.g., EU Waste Framework Directive).

✅ Enhance brand reputation as an eco-conscious enterprise.

As an important link in the circular economy industry chain, plastic crusher not only solves the problem of waste plastic pollution, but also creates economic value through resource regeneration.

With the technology iteration and policy support, its application scenarios will continue to expand, contributing to global sustainable development. Choosing an efficient and reliable plastic crusher is a wise choice for enterprises to realize green transformation.

Ready to upgrade your recycling operations?

Contact us today for a free consultation and quote tailored to your industry and region!

Fudemetal Crusher

Fudemetal Crusher