Scrap metal briquetting machine

A multifunctional scrap iron compactor

Scrap iron compactor is a mechanical equipment widely used for metal waste, including various types such as manual, hydraulic, and electric.

By first compacting and then packaging, the metal waste is compressed into blocks, reducing storage and transportation costs.

| Name | Scrap iron compactor | Applicable scope | Steel mills, recycling and processing industries |

| Driving method | Hydraulic or diesel | Control system | Fully automatic (PLC control panel) |

Metal briquetting machine operation video

Metal Briquette Machine,Place the materials that need to be packaged and formed in the metal forming machine material box, use hydraulic oil cylinders to push and compress the materials that need to be packaged in the material box, and ultimately form various styles and sizes of packaging blocks, which are formed in one go and convenient for transportation.

Metal Compactors Product Description

forming machine metal, iron wire aluminum profile corner material packaging machine, supports customization, is a multi-purpose scrap iron compactor (packaging machine). The metal is compressed and packaged to reduce volume, making it easy to load and box, and more importantly, to improve the melting rate.

Small aluminum chip pressing machine

Large scale aluminum chip pressing machine

The characteristics of scrap iron compactor

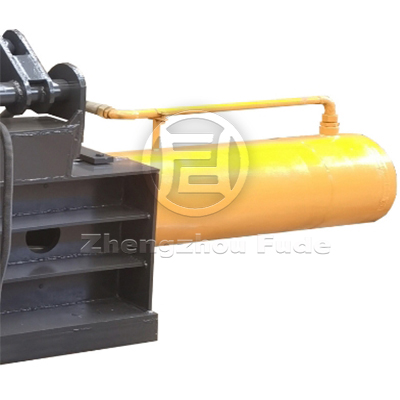

1. Hydraulic metal briquetting machine,All models are driven by hydraulic pressure and can be manually operated or automatically controlled by PLC.

2. Metal briquetting machine,There are various ways to release packages, including flipping, side pushing, forward pushing, and manual pickup.

3. Hydraulic baler,Multiple models are available for selection: different pressures, material box sizes, and package block sizes and shapes.

Independent control lever

Intelligent control electric box

High pressure chrome plated oil cylinder

Product Features of Metal Powder Briquetting Machine

- Scrap metal briquetting machine,The transportation of metal materials after pressing is convenient, which can effectively reduce transportation costs and increase transportation efficiency.

- Horizontal metal briquetting machine,After pressing, the metal is easily crushed for secondary processing.

- Metal Briquetting Press,Block metal materials are easier to store compared to metals, which can save a lot of warehouse space.

- Metal briquete machin,The pressed metal greatly facilitates its use and reprocessing.

Wide use of scrap iron briquetting machine

Hydraulic packaging machines can extrude various metal waste materials (such as scraps, shavings, scrap steel, scrap aluminum, scrap copper, scrap stainless steel, scrap cars, etc.) into qualified furnace materials in various shapes such as rectangular, octagonal, cylindrical, etc. This can not only reduce transportation and smelting costs, but also improve furnace feeding speed.

Before pressing aluminum chips into blocks

After pressing aluminum shavings into blocks

After pressing the scrap cans into blocks

Before pressing the scrap cans into blocks

Before packaging scrap copper

After packaging the scrap copper

After the steel bars are pressed into blocks

Before pressing steel bars into blocks

Steel mills, recycling and processing industries, non-ferrous and ferrous metal smelting industries, and renewable utilization industries

Product Parameters of Horizontal Baler

| Model | Nominal thrust (KN) | Size of pressure box (mm) | Packaging block size (mm) | Package weight (Kg) | Yield (t/h) | Power allocation (Kw) |

| 63 | 630 | 1000*600*500 | 190*190 | 15~30 | 0.4~0.8 | 7.5 |

| 100 | 1000 | 1000*700*550 | 230*230 | 30~40 | 0.6~1.2 | 11 |

| 125 | 1250 | 1200*700*600 | 300*300 | 60~80 | 1.2~1.5 | 15 |

| 135 | 1350 | 1400*600*600 | 600*240 | 50~75 | 1.5~2.8 | 22 |

| 160 | 1600 | 1600*1000*800 | 400*400 | 110~150 | 2.2~3.0 | 22 |

| 200 | 2000 | 1800*1400*900 | 450*450 | 210~300 | 3.0~5.0 | 22*2 |

| 250 | 2500 | 2000*1750*1000 | 500*500 | 250~280 | 5.0~6.3 | 22*2 |

| 315 | 3150 | 2500*2000*1200 | 500*500 | 250~360 | 4.0~6.5 | 37*2 |

| 400 | 4000 | 3000*2000*1200 | 500*600 | 250~380 | 6.8~8.0 | 45*2 |

Hydraulic metal briquetting machine suppliers

Hydraulic metal briquetting machine price,On site feedback photos of customers from different regions suppressing different materials

Iron filings pressing block site

Reinforcement block pressing site

Scrap iron sheet pressing site

Metal waste pressing blocks

Aluminum chip pressing block site

Metal briquetting machine for sale, boxed and shipped

Hydraulic scrap metal baler,The factory arranges different logistics vehicle sizes according to the customized machine models and sizes of different customers, ensuring timely delivery and reliable transportation

Shipping from US customers

Malaysian customer loading and shipping

How to choose a metal forming machine

When choosing a metal scrap iron compactor, attention can be paid to the material, process, structural design, and other aspects of the product, as well as whether there is a professional research and development team and technical support.

Choose the appropriate equipment to increase the density of metal waste, reduce its occupancy space, and reduce storage and transportation costs. At the same time, pay attention to the reliability and durability of the equipment, as well as the maintenance costs in the later stage. Suitable models can be customized according to one’s own budget and actual needs.

Fudemetal Crusher

Fudemetal Crusher