Single axis industrial shredder

Working video of a Single Shaft Shredder

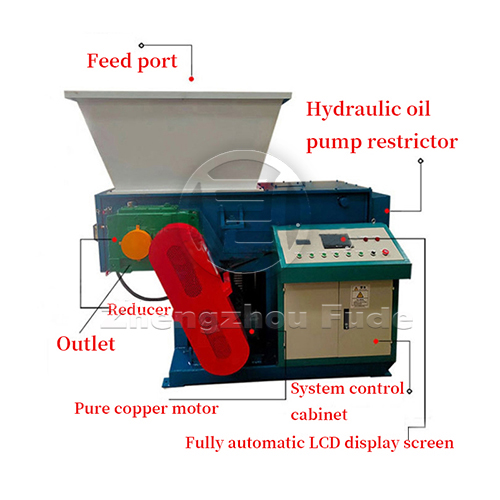

Small metal shredder The material enters the machine case from the feeding hopper, and the pushing box is pushed by the hydraulic cylinder to push the material towards the rotating knife roller.

The rotating and fixed knives crush the material, and the crushed material falls through the screen.

It is then transported to the next process or collected and packaged through auxiliary conveying equipment.

What is a single axis crusher?

The metal shredder machine can meet the waste recycling requirements of various industries, suitable for plastic, paper, wood, fiber, rubber, household waste recycling and treatment, and has a wide variety of recyclable materials.

Suitable for recycling various large solid materials, difficult to handle materials, plastic containers and barrels, and plastic pads. The discharge size can be reduced to 20mm according to different needs.

And we can provide various feeding hoppers according to customer needs. This device has low speed blade rotation, low noise, and is more economical.

Single machine shredder

Forced feeding shredder

Metal shredder for sale :Product advantages

- High chromium Tool steel, adjustable gap, durable

- Large inertia wheel, high torque, and high production capacity

- Heavy duty bearings and dust prevention devices, with soundproof partitions, can effectively prevent vibration and noise

- Interlocking design of safety devices to protect the safety of machines and personnel

- Alternating cutting effectively reduces dust and saves energy

- Motor overload protection, overload adjustment

- Mobile casters for easy placement

- Removable design for easy maintenance and upkeep

Shredder structure

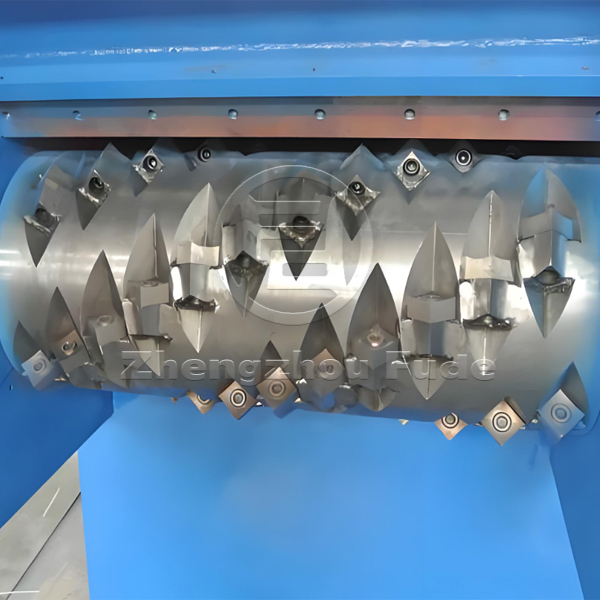

Single axis shredder knife roller

The working principle of a shredder metal

Commercial metal shredder: The thickness and quantity of shredder knives can be changed according to different materials. When crushing hollow materials, a pressing device can be equipped to increase production. The thickness of the shredder blade is divided into 15mm, 20mm, 40mm, 50mm, 75mm, and 100mm. The blade body can be selected based on the particle size of the object after crushing.

Raw material

During material processing

Tearing effect

Industrial tire shredder is widely used

- Various hollow containers: plastic beverage cans, plastic barrels, iron barrels, packaging boxes, packaging barrels

- Waste household appliances: TV sets, washing machines, refrigerator shells

- Pipes: large pipes, fittings, PE pipes

- Waste templates: wooden pallets, plastic pallets, forklift pallets

- Waste tires: car tires, truck tires

- Scrap metals: automotive casings, aluminum alloys, scrap aluminum castings, engine casings, lead, and steel plates with a thickness of less than 10mm

- Kitchen waste, household waste, animal carcasses, RDF derivatives, medical waste, biological orange stems, garden waste

- Rubber head material, paper mill twisted rope

Big Blue Bucket

The crushing effect of the large blue barrel

Fruit basket crushing effect

Fruit basket

Scrap iron

Scrap iron shredding effect

Crushing effect of waste cardboard boxes

Waste cardboard box

Old tires

Tearing effect of waste tires

metal shredder machine price:Selling feedback

Metal shredder manufacturers On site feedback photos of customers from different regions crushing different materials

Tire crushing site

Foam crushing site

Paper box crushing site

Rubber shredder:Customer shipment site

The factory arranges different logistics vehicle sizes according to the customized machine models and sizes of different customers, ensuring timely delivery and reliable transportation

Customized for Australian customers

Customized by Russian customers

Customized for Canadian customers

How to choose a single shaft plastic shredder

When it comes to the motor of the shredder, it is important to choose a guaranteed motor. Secondly, the quality of the bearings directly affects the factory power and quality of the shredder. In addition, the thickness of the steel plate must meet certain requirements.

Finally, the blade is important for the shredder. Choosing the appropriate blade will affect the later production process. The material and shape of the blade are different, and the appropriate machine model can be customized according to customer needs.

Fudemetal Crusher

Fudemetal Crusher