Metal Briquette Machine

A metal briquetting machine for pressing scrap iron/aluminum chips

Steel bar compactor is a widely used mechanical equipment for metal residual materials, which includes various types such as manual, hydraulic, and electric. By first compacting and then packaging, the metal waste is compressed into blocks, reducing storage and transportation costs.

| Name | metal briquetting machine | Applicable scope | Steel mills, recycling and processing industries |

| Driving method | Hydraulic or diesel | Control system | Fully automatic (PLC control panel) |

Metal briquette machine operation video

Metal briquete machin,Place the materials that need to be packaged and formed in the metal forming machine material box, use hydraulic oil cylinders to push and compress the materials that need to be packaged in the material box, and ultimately form various styles and sizes of packaging blocks, which are formed in one go and convenient for transportation.

What is a metal scrap forming machine

The steel bar compactor is an electromechanical integrated and highly automated compactor. Its compactor equipment has good rigidity, toughness, stability, beautiful appearance, convenient operation and maintenance, safety and energy conservation, and low investment cost in equipment foundation engineering. These characteristics are one of the reasons why it has been praised by new and old customers.

Steel bar packing machine

Small hydraulic packaging machine

Working Principle of Horizontal Metal Briquetting Machine

Scrap metal briquetting machine,Place the materials that need to be packaged and formed in the metal forming machine material box, use hydraulic oil cylinders to push and compress the materials that need to be packaged in the material box, and ultimately form various styles and sizes of packaging blocks, which are formed in one go and convenient for transportation.

Independent control lever

Intelligent control electric box

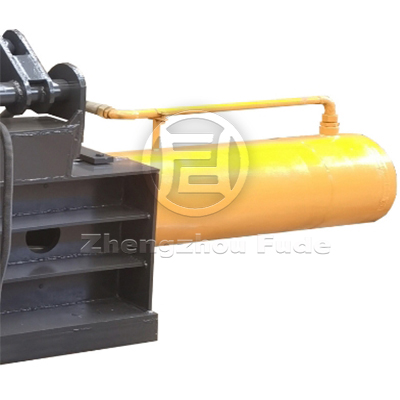

High pressure chrome plated oil cylinder

Product Advantages of Aluminum Chip Briquetting Machine

- Metal compactor,The discharge form can be selected from different methods such as flipping the bag, pushing the bag, or manually picking up the bag (carrying the bag).

- Installation does not require foot screws, and diesel engines can be used as power in areas without power supply.

- Scrap metal compactors,There are ten levels of working extrusion pressure from 63 tons to 400 tons for users to choose from, with production efficiency ranging from 4 tons per shift to 40 tons per shift.

- Can Briquetting Machine,The size of the compression chamber and the shape and size of the package can be customized according to user requirements.

- Baler metal compactor,The machine can be equipped with loading box blades and a fast system, making operation more convenient;

- Metal powder briquetting machine,The main components are imported components, and the oil seal adopts brand oil seals, greatly improving the quality and service life of the machine;

- Scrap metal briquetting machine,The side pressure oil cylinder of a 125 ton machine or above can be equipped with a fast gear, which is faster than packaging machines produced in the same industry.

Metal forming machines for a wide range of applications

Hydraulic packaging machines can extrude various metal waste materials (such as scraps, shavings, scrap steel, scrap aluminum, scrap copper, scrap stainless steel, scrap cars, etc.) into qualified furnace materials in various shapes such as rectangular, octagonal, cylindrical, etc. This can not only reduce transportation and smelting costs, but also improve furnace feeding speed.

Before pressing copper scrap into blocks

Before pressing copper scrap into blocks

After the steel bars are pressed into blocks

Before pressing steel bars into blocks

Before pressing the can block

After pressing the can block

After pressing aluminum shavings into blocks

Before pressing aluminum chips into blocks

Steel mills, recycling and processing industries, non-ferrous and ferrous metal smelting industries, and renewable utilization industries

Scrap metal molding machine product parameters

| Model | Nominal thrust (KN) | Size of pressure box (mm) | Packaging block size (mm) | Package weight (Kg) | Yield (t/h) | Power allocation (Kw) |

| 63 | 630 | 1000*600*500 | 190*190 | 15~30 | 0.4~0.8 | 7.5 |

| 100 | 1000 | 1000*700*550 | 230*230 | 30~40 | 0.6~1.2 | 11 |

| 125 | 1250 | 1200*700*600 | 300*300 | 60~80 | 1.2~1.5 | 15 |

| 135 | 1350 | 1400*600*600 | 600*240 | 50~75 | 1.5~2.8 | 22 |

| 160 | 1600 | 1600*1000*800 | 400*400 | 110~150 | 2.2~3.0 | 22 |

| 200 | 2000 | 1800*1400*900 | 450*450 | 210~300 | 3.0~5.0 | 22*2 |

| 250 | 2500 | 2000*1750*1000 | 500*500 | 250~280 | 5.0~6.3 | 22*2 |

| 315 | 3150 | 2500*2000*1200 | 500*500 | 250~360 | 4.0~6.5 | 37*2 |

| 400 | 4000 | 3000*2000*1200 | 500*600 | 250~380 | 6.8~8.0 | 45*2 |

Hydraulic metal briquetting machine for sale

Hydraulic metal briquetting machine price,On site feedback photos of customers from different regions suppressing different materials

Metal waste pressing blocks

Aluminum chip pressing block

Scrap iron sheet pressing block

Hydraulic metal briquetting machine suppliers:Loading and shipping

Metal equipment manufacturers,The factory arranges different logistics vehicle sizes according to the customized machine models and sizes of different customers, ensuring timely delivery and reliable transportation

Shipping from US customers

Delivery site for German customers

How to choose a metal compactor?

When choosing a metal scrap iron compactor, attention can be paid to the material, process, structural design, and other aspects of the product, as well as whether there is a professional research and development team and technical support.

Choose the appropriate equipment to increase the density of metal waste, reduce its occupancy space, and reduce storage and transportation costs. At the same time, pay attention to the reliability and durability of the equipment, as well as the maintenance costs in the later stage. Suitable models can be customized according to one’s own budget and actual needs.

Fudemetal Crusher

Fudemetal Crusher