Vertical Metal Briquetting Machine

Multi-functional briquetting machine for scrap metal shavings, wood chips use

| Name | Metal scrap briquette machine |

| Customization | Support customization according to customer requirements |

| type | Vertical Hydraulic Baler |

| Applicable scope | Various metal scraps (cast iron scraps, copper scraps, aluminum scraps, etc.) |

In the realm of industrial metal processing, managing metal scraps—such as iron filings, aluminum chips, and copper dust—has long posed challenges. These loose materials not only occupy significant storage space but also pose environmental risks and increase transportation costs.

Enter the vertical metal scrap briquetting machine, a revolutionary device designed to compress these scattered metal wastes into compact, high-density briquettes, transforming waste management into a profitable and eco-friendly process.

Aluminum chip briquetting machine product introduction

The fully automatic metal cake pressing machine can directly cold press powdered iron chips, steel chips, copper chips, aluminum chips, mineral powder, etc. into cake blocks for storage, transportation, and furnace recycling and reuse.

After being compressed into blocks, the loss for recycling in the furnace is extremely low. The entire production process does not require heating, additives, or other processes, and is directly cold pressed into shape, ensuring that the original material remains unchanged while forming.

For example, using cast iron filings instead of cast pig iron after forming. For castings made of special materials, recycling has greater significance.

Small metal chip cake press

Large scale metal waste cake press

Core Functionality: High-Pressure Compaction

he vertical metal scrap briquetting machine operates on a simple yet powerful principle: mechanical or hydraulic pressure. Here’s how it works:

- Feeding: Metal scraps are loaded into the machine’s hopper via conveyor belts or manual input.

- Pre-compression: A preliminary compression stage removes trapped air and oil, ensuring uniform density.

- High-Pressure Molding: The main hydraulic cylinder exerts hundreds of tons of pressure, compressing the scraps into cylindrical or custom-shaped briquettes.

- Ejection: The finished briquettes are automatically discharged, ready for storage or transportation.

This process reduces the volume of metal scraps by 70–90%, significantly cutting storage and logistics expenses while enhancing the material’s recyclability.

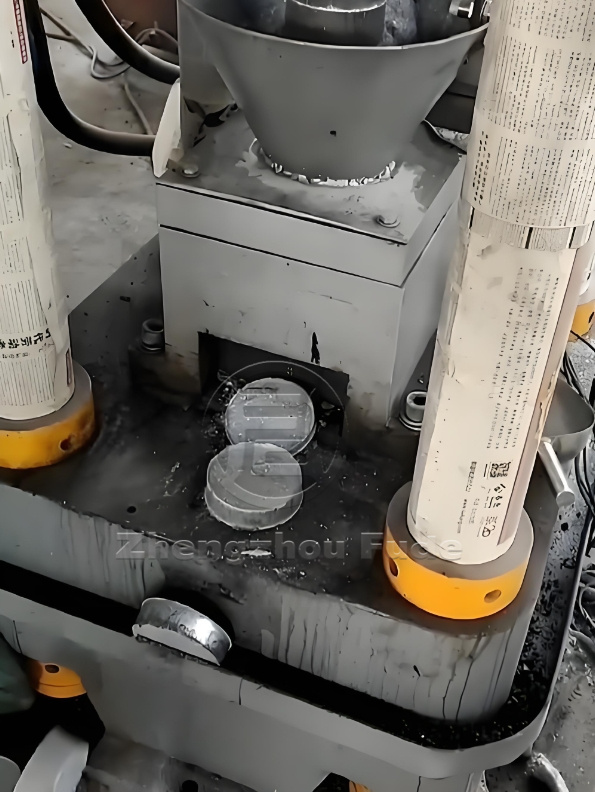

Detailed diagram display of metal cake press

- Equipment host: The upper and lower crossbeams and sliders are made of integral cast steel, which will not deform or damage after long-term use; The surface of the column is coated with hard metal, which is wear-resistant and not rusty.

- Hydraulic system: Adopting an optimized hydraulic system, there is no hydraulic impact during operation; Select high-quality hydraulic components to improve the service life of the equipment; High pressure oil pipes to avoid equipment oil leakage.

- Electrical system: PLC programmable controller is selected to control the operation of the equipment through buttons; Adjust the technical parameters through the LCD display screen according to the working situation of the equipment.

- Forming mold: Made of high-quality wear-resistant steel through special processing, it not only has high precision but also is wear-resistant; Partially worn and detachable, reducing replacement costs.

Device host

Hydraulic system

Electrical system

Forming mold

Applications Across Industries

The vertical briquetting machine is a versatile solution for sectors generating large volumes of metal waste:

- Automotive Manufacturing: Compresses aluminum and steel shavings from engine block machining.

- Aerospace: Handles titanium and nickel alloys with precision, preserving material integrity.

- Metal Fabrication: Processes mixed scraps from CNC milling and laser cutting.

- Waste Recycling Centers: Standardizes irregular metal pieces for easier sorting and resale.

Choosing the Right Machine

When selecting a vertical briquetting machine, consider:

- Material Type: Different metals require varying pressure levels (e.g., aluminum needs less force than steel).

- Throughput: Match the machine’s cycle time to your daily waste generation.

- Automation Needs: Opt for PLC controls if integrating with existing systems.

- After-Sales Support: Prioritize manufacturers offering spare parts and technical training.

Working Principle of Metal Cake Press

Scrap metal compactor The process of compressing and curing loose metal powder. Firstly, fill the metal powder into the workshop of the machine and apply high pressure on it.

High pressure causes mutual forces between metal powder particles, and the powder particles gradually combine together. Next, by heating or other means, the structure of the metal powder cake will be further solidified to form a solid metal cake.

Throughout the process, the bonding force between powder particles and the pressure applied by the machine determine the quality and performance of the product.

Product Analysis

Scrap Metal Compactor Product Features

1. Machine tool structure, simple, economical, and practical.

2. The hydraulic control action is reliable, with a long service life and small hydraulic impact, reducing the connection pipeline and leakage points.

3. Electrical control system, reliable operation, objective action, and convenient maintenance.

4. It adopts button centralized control and has three operation modes: adjustment, manual, and semi-automatic.

5. By selecting through the operation panel, two forming processes, fixed stroke and constant pressure, can be achieved, with functions such as pressure maintaining.

6.The working pressure of the slider, as well as the travel range of the no-load fast down and slow work advance, can be adjusted according to the process needs.

Note: Work pressure, work height, and running speed can be customized according to user requirements.

Scope of application of metal briquetting machine

Metal powder briquetting machine mainly used for cold pressing cake blocks of powdered or granular copper shavings, aluminum shavings, cast iron shavings, ball milled cast iron shavings, sponge iron, steel shavings, iron ore powder, silicon powder, slag powder, and other non-ferrous metal shavings.

Metal Chip Briquetting Machine: It can directly cold press the powder and granular cast iron chips, steel chips, copper chips, aluminum chips, high quality mineral powder, etc. into cake blocks, and the loss is very low after pressing into blocks and casting into furnace for recycling and use.

The whole production process does not need to add temperature, add additives or other processes, direct cold press molding, molding at the same time to ensure that the original material remains unchanged. For example, cast iron chips can be used instead of cast pig iron after molding.

How to choose a metal cake press?

- Body material: High quality stainless steel material must be selected, and the surface of the body should be smooth, hard, and able to withstand high pressure and temperature.

- Capacity size: It is necessary to choose the appropriate capacity according to actual needs. If the capacity is too small, it will affect the efficiency of cookie making, while if the capacity is too large, it will cause waste.

- Operation mode: A handle that is easy to operate and can rotate freely should be selected to make operation more convenient.

- Safety performance: Safety performance must be considered and products with safety valves and explosion-proof devices must be selected.

Key Advantages

Cost Efficiency

- Reduced Storage Space: Compact briquettes minimize warehouse footprint, freeing up valuable floor space.

- Lower Transportation Costs: Denser briquettes mean fewer trips to recycling facilities, saving on fuel and labor.

- Higher Recycling Value: Pre-compressed metal melts faster and with less oxidation, improving yield and reducing energy consumption in foundries.

Environmental Compliance

- Dust and Oil Control: Enclosed designs prevent metal dust and cutting fluids from contaminating the workspace, meeting stringent environmental regulations.

- Resource Conservation: By recycling metal scraps, industries reduce reliance on virgin ore mining, lowering carbon emissions and promoting circular economies.

Operational Simplicity

- Automation: Many models feature PLC controls for seamless integration into production lines, with adjustable parameters for different metals.

- Low Maintenance: Durable components like hardened steel molds and self-lubricating bearings ensure longevity with minimal downtime.

- Safety: Built-in sensors and emergency stops protect operators from accidents.

Metal briquetting machine for sale, customer use site

We consulted and followed up with customers from Austria, Malaysia, the United States, Russia, Indonesia and other countries regarding the use of metal cake presses, and they provided satisfactory responses.

Austrian customer presses square aluminum shavings

Malaysian customers suppress aluminum shavings

The vertical metal scrap briquetting machine is not just a tool—it’s a strategic investment in efficiency, profitability, and environmental stewardship.

By transforming waste into valuable briquettes, manufacturers can unlock hidden savings while contributing to a greener planet.

For industries seeking to optimize their metal recycling processes, this technology represents a leap forward into the future of sustainable manufacturing.

Fudemetal Crusher

Fudemetal Crusher