What is a car shredder?

773A car shredder is a mechanical device specifically designed for processing large pieces of automotive materials.

View detailsSearch the whole station

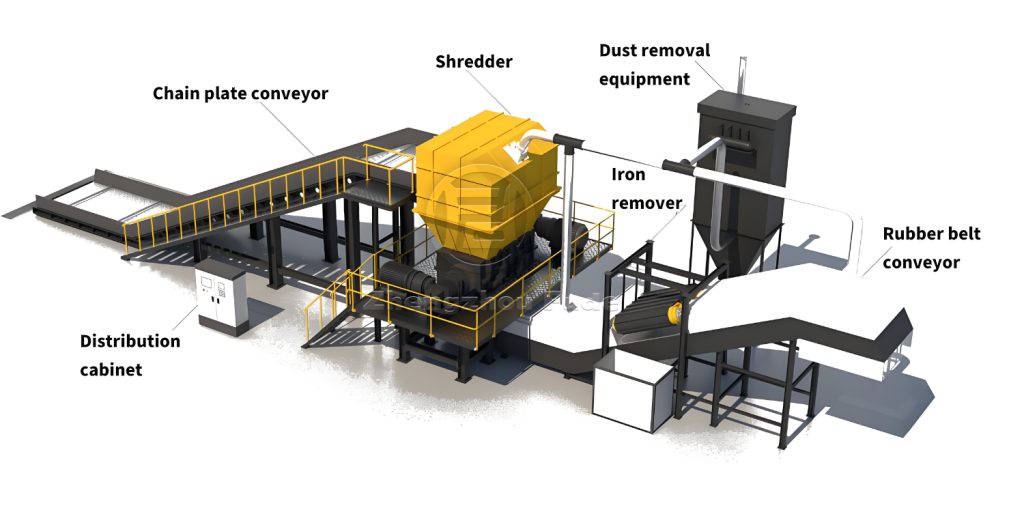

Double axis shredder is an efficient crushing equipment. It mainly reduces the size of materials through the shearing, tearing, and squeezing effects between two relatively rotating cutting tools. This device has a wide range of applications in multiple fields, including but not limited to the recycling and treatment of waste plastics, rubber, wood, household appliances, automotive plastics, packaging waste, and other waste materials.

The working principle of a dual axis shredder mainly relies on the rotational motion of two main axes, and crushes materials through the mutual cooperation and shear action between the cutting tools. After the material is fed into the machine, it is gradually broken into small pieces by forces such as shearing, impact, and compression from high-speed rotating cutting tools. The crushed material is filtered through a sieve to achieve the desired particle size distribution.

Zhengzhou Fude Machinery integrates research and development, manufacturing, and sales. We have a professional technical team that deeply understands customer needs, recommends and answers equipment questions for customers, teaches operation techniques, and produces metal compactors, shredders, copper rice machines, plastic crushers, cake presses, and more. If you want to learn about the metal processing, recycling and reuse industry, please consult us.

A car shredder is a mechanical device specifically designed for processing large pieces of automotive materials.

View detailsMetal crusher is a professional machinery mainly used for crushing and processing large-sized solid materials to the required size

View detailsHow Do You Build a Complete and Efficient Recycling Line?Work video of Double-shaft shredder production lineWood shredder material crushing principleThe purpose of a dual axis crusherBasic structure of industrial metal shreddersHow to choose the r...

View detailsA shredder is an important mechanical equipment mainly used for coarse crushing of various materials, making them smaller in size and easier for subsequent processing or recycling.

View details