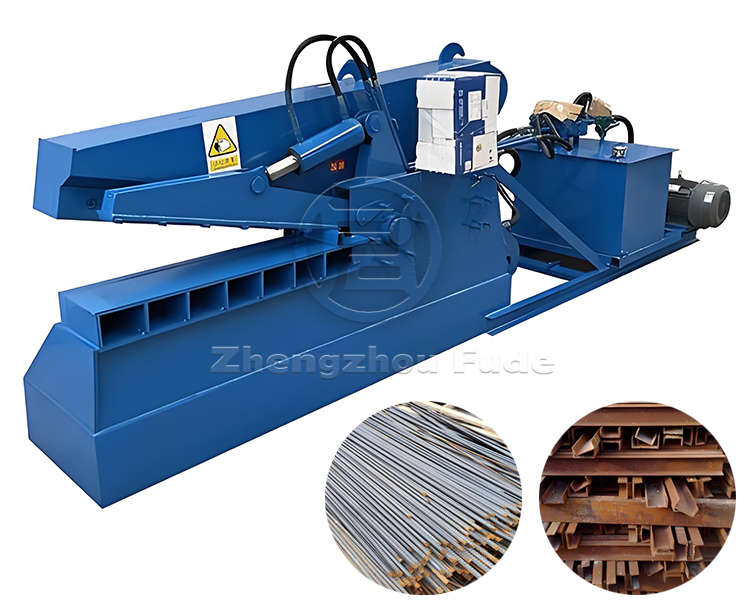

Crocodile shearing machines are mainly used in the waste material recycling and processing industry, as well as in the processing of metal materials by small and medium-sized steel mills. Specifically, its uses mainly include the following aspects:

Main application areas

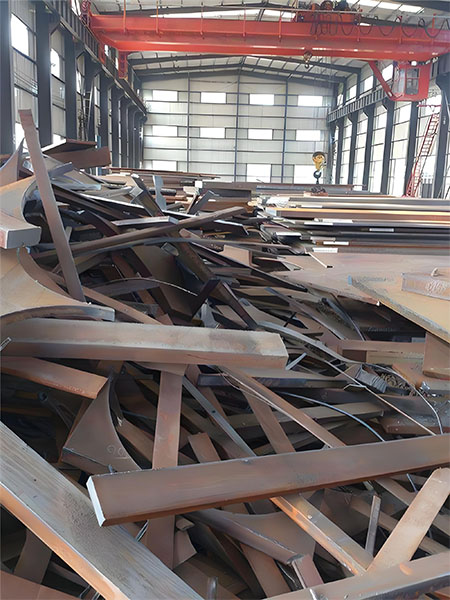

- Recycling and processing of waste materials: In waste recycling stations, metal dismantling plants and other places, crocodile shearing machines perform cold cutting processing on waste metals, such as scrap iron, scrap steel, aluminum plates, copper plates, etc., to make them qualified furnace materials or other reusable materials.

- Metal processing and manufacturing: In metal processing plants, smelting and casting plants, crocodile shearing machines accurately cut various metal materials such as steel bars, steel pipes, steel plates, angle irons, channel steels, square steels, round steels, etc. to meet production needs.

Main processing objects

- Scrap metal: Crocodile cutters are often used to process various scrap metals, such as scrap iron, scrap steel, scrap aluminum, scrap copper, etc. After being sheared, these scrap metals can be reused or used as smelting materials.

- Metal material scraps: During the metal processing and manufacturing process, a large amount of scraps, waste materials, and non-conforming products are generated. The crocodile shearing machine can cut these scraps into metal materials with uniform specifications that are easy to recycle or reuse.

- Metal profiles: such as steel bars, steel pipes, steel plates, angle irons, channel steels, square steels, round steels, etc. These metal profiles can be cut by crocodile shearing machines during processing or after disposal to meet different usage or recycling needs.

- Nonferrous metal materials: In addition to common black metals such as iron and steel, crocodile shearing machines can also process non-ferrous metal materials such as aluminum ingots, copper plates, and color steel tiles, providing convenience for the recycling and utilization of non-ferrous metals.

- Other metal items, such as car bodies, waste machinery and equipment, metal products, etc., contain a large amount of metal components. Through the processing of crocodile shearing machines, the metal can be effectively separated from other materials for subsequent recycling and reuse.

Working characteristics

- Hydraulic Drive: The crocodile shearing machine adopts hydraulic transmission, which has the advantages of small size, light weight, low inertia, low noise, smooth action, and easy operation.

- Multiple working modes: The equipment usually has three working modes: jog, manual, and automatic, which can be selected according to actual needs to improve work efficiency and flexibility.

- High shear force: The crocodile shearing machine can provide a large shear force to meet the cutting needs of metal materials of different specifications and materials.

- Easy to maintain: The device has a simple structural design, low maintenance costs, and is easy to implement overload protection, ensuring safe operation of the equipment.

Application scenario examples

- At the waste recycling station, crocodile cutters quickly cut and process piles of scrap metal to improve recycling efficiency.

- In small and medium-sized steel mills, crocodile cutters are used to cut and process the scraps and non-conforming products generated during the production process, providing qualified furnace materials for smelting.

In summary, crocodile shearing machines play an important role in the recycling and processing of waste materials and metal processing and manufacturing industries, and are one of the indispensable equipment in modern industry.

Zhengzhou Fude Machinery integrates research and development, manufacturing, and sales. We have a professional technical team that deeply understands customer needs, recommends and answers equipment questions for customers, teaches operation techniques, and produces metal compactors, shredders, copper rice machines, plastic crushers, cake presses, and more. If you want to learn about the metal processing, recycling and reuse industry, please consult us.