How does the vertical metal chip press work?

688The vertical metal chip compactor compresses metal waste into cakes through high-pressure physical compression

View detailsSearch the whole station

The can compactor is mainly used to process discarded aluminum cans and other metals, quickly compressing them into block shapes through compression technology, thereby achieving the goal of reducing volume, facilitating storage and transportation. The main functions of the equipment are reflected in the following aspects:

Metal packaging materials such as cans often occupy a large volume in their discarded state, which not only increases the difficulty of storage but also raises the cost of transportation. The can compactor uses efficient compression technology to quickly compress these discarded cans into tight and sturdy blocks, greatly reducing their volume, saving storage space, and facilitating subsequent transportation and processing.

Due to the ability of the can compactor to compress discarded cans into smaller blocks, more materials can be loaded during transportation, thereby reducing the transportation cost per unit of material. This is undoubtedly an important economic advantage for the waste recycling industry.

After compression treatment, metal packaging such as cans can be more easily recycled and reused. Recycled cans and other metals can be reprocessed into new metal materials through processes such as smelting, achieving the recycling of resources. This not only helps to reduce resource waste, but also helps to lower environmental pollution.

In summary, the can compactor plays an important role in the treatment of waste metal packaging materials. By reducing volume, lowering transportation costs, promoting resource recycling and reuse, and possessing efficient and stable technical characteristics and advantages, it provides strong support for environmental protection and waste recycling industries.

Zhengzhou Fude Machinery integrates research and development, manufacturing, and sales. We have a professional technical team that deeply understands customer needs, recommends and answers equipment questions for customers, teaches operation techniques, and produces metal compactors, shredders, copper rice machines, plastic crushers, cake presses, and more. If you want to learn about the metal processing, recycling and reuse industry, please consult us.

The vertical metal chip compactor compresses metal waste into cakes through high-pressure physical compression

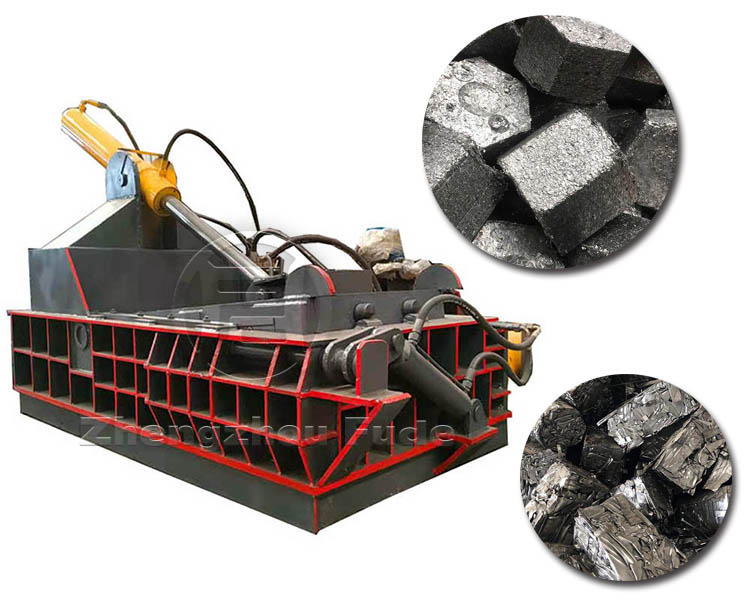

View detailsMetal briquetting machine is a device that directly cold compresses various metal waste materials under high pressure. It plays an important role in the fields of waste metal recycling, metallurgical industry, casting industry, etc.

View detailsMetal compactor is an efficient and energy-saving equipment widely used in the field of metal material processing and reuse.

View detailsMetal block press is a multifunctional pressing and processing equipment, mainly used to directly cold press various metal waste materials under high pressure for storage, transportation, and recycling.

View details